Thousands of underwater hours

The fully tested SuperLite® 17B Commercial Diver’s Helmet set the working standard for the commercial diving industry worldwide...

Many thousands of underwater hours have proved the design to be dependable, comfortable and extremely rugged.

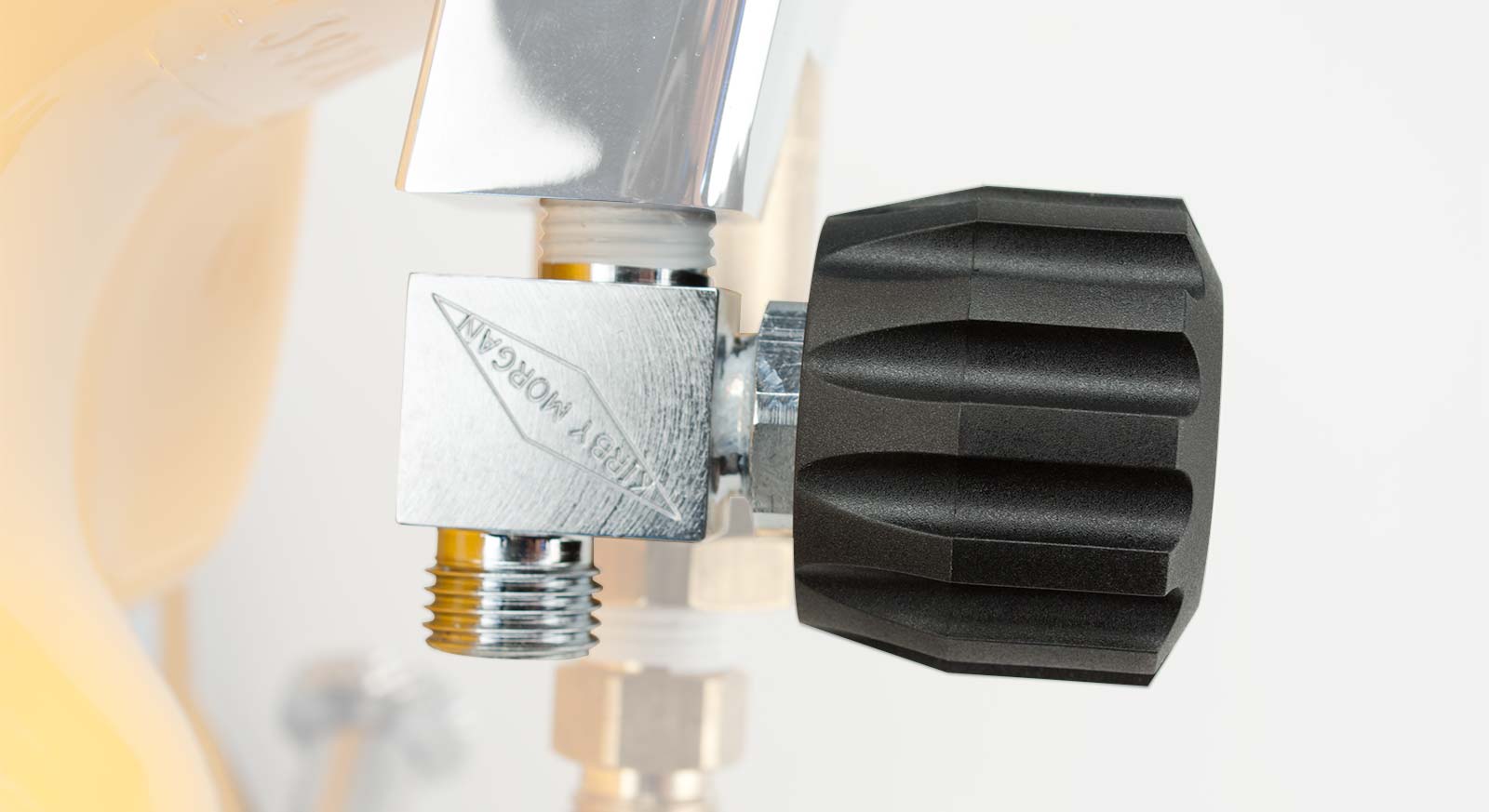

The helmet system consists of two pieces: the neck dam/yoke and the helmet. The diver slips on the angled neck dam with the attached yoke. The neck clamp is then slipped onto the helmet and locked. The locking system not only seals the neck dam to the helmet but also secures the front of the yoke.

The SuperLite® 17B also includes our Quad-Valve Exhaust System which retrofits to many of our helmets. This exhaust has exceptionally low exhalation resistance that you must experience to appreciate. The SL 17A/B Helmet Retainer (chin strap) along with the SL 17A/B Yoke Retainer (yoke strap) make it virtually impossible to have the hat come loose. These are standard on all SL 17B helmets and will retrofit to all previous SL 17 A/B Helmets.

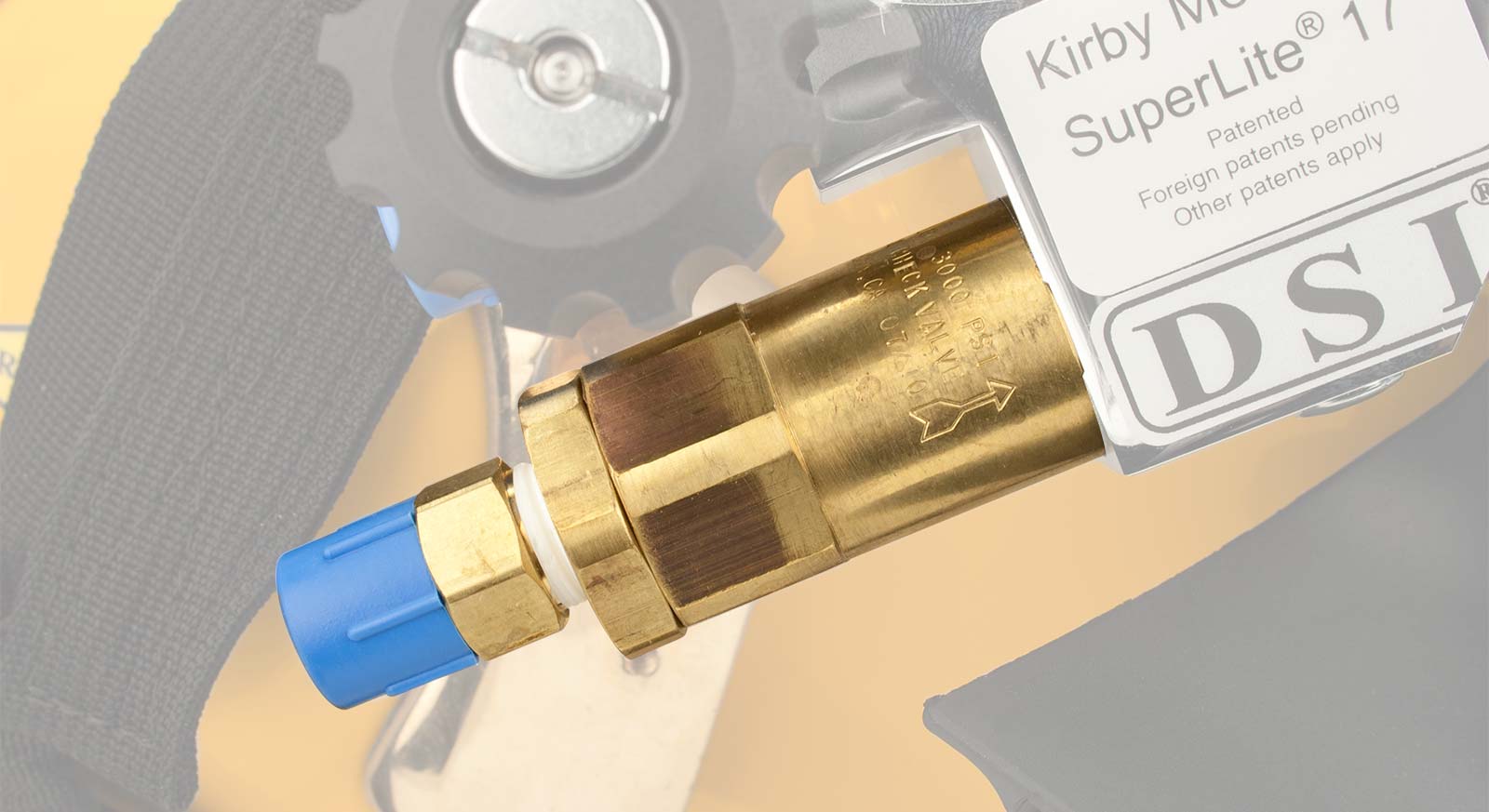

The SuperLite® 17B offers comprehensive head protection, an adjustable demand breathing system for gas economy, antiflooding features, rapid emplacement, a neck dam clamp that mechanically breaks a low-pressure lock, and a trim to fit angled neck dam which seats the helmet comfortably, especially when working in the face down position. The pull pin neck clamp release provides a system for prevention of accidental helmet removal.

Part Numbers

500-010 SL 17B Helmet w/Posts

500-011 SL 17B Helmet w/MWPC