Kirby Morgan History

In 1966, a company was formed that would change the face of commercial diving forever. The Kirby Morgan Corporation was dedicated to the development of lightweight, comfortable, professional diving gear. Through the years we have been known by different names - Deep Water Development in 1969 and Diving Systems International 1977. Though the names changed, the commitment to the divers never did. Now we have come full circle and are once again Kirby Morgan, a name that has become synonymous with quality and cutting-edge design throughout the world. Kirby Morgan Dive Systems, Inc., based in Santa Maria, California, continues to provide the diving industry with our outstanding products, quality parts and service.

m KMDSI shall continue designing and manufacturing the highest quality underwater breathing equipment available while maintaining a strong reputation for safety and excellent customer service. Delivering quality products in a timely manner is made possible by a team of conscientious individuals who take pride in the KMDSI name and products.

Kirby's First Mask

Mask

The First Bob Kirby Mask. Bob Kirby said this about the mask, "In the early 1950s, I was a navy diver on the sub tender U.S.S Nereus in San Diego, but was restless. I started living a double life and was living on a fishing boat part of the time, and on the Nereus the rest. I started diving commercially in my off-duty hours and hooked up with Lad Handleman in 1955. I was introduced to him by Jerry Todd in San Diego. Lad was diving abalone with a guy called Rex Rosenberry and they were using Widolf masks. Now these were not the fancy oblong Widolfs with the nice face seals that turned up later. No, these were the old circular ones which were always interesting to dive. The brass ones would sink and the aluminum ones would float. Rex had terrible eyesight and could not wear glasses inside the Widolf. He and Lad let me dive one of their Widolfs and, like them, I got just a terrible pain from how tight the damn thing was. It was a gruesome experience. I had met a navy ship yard welder called Henry Hanson who dove a bit with Chuck Snell part time. Henry was pretty unique as he was a black guy, and there were not many black divers around those days. Henry did not like the Widolfs at all, and made several of his own style from stainless steel. These were an absolute work of art, marvelous! So I designed my mask after Henry’s. Like him, I constructed mine of stainless steel and made a few changes by trial and error. This was my first mask and it worked just great. It got me started on making dive gear." It is now on display at the Santa Barbara Maritime Museum.

MMX-1

Mask

Morgan Mask, Experimental 1. This mask was our first fiberglass free-flow mask. Air was supplied through a non-return valve at whatever flow the compressor could put out. Four of these were made and used by commercial abalone divers.

MMX-2

Mask

The Morgan Mask, Experimental 2. Incorporated a Sportsways demand regulator. Two of these masks were made using the MX-1 mask as a starting point. There was no side block.

MM-3

Mask

Morgan Mask 3. This was the first of our masks that had a side block and a demand regulator. The use and positioning of the side block and regulator set the standards for future masks and helmets. A non-adjustable SCUBA-Pro® demand regulator was used. Twenty of these masks were sold to Ocean Systems in 1964.

KMAH-1

The Kirby Morgan Commercial Air Helmet. This helmet was manufactured in 1965. (Kirby and Morgan were working together as a partnership prior to the Kirby Morgan Corporation formation.) The breastplate was made by Yokohama Diving Apparatus. The helmet was spun from two sheets of copper by Hummel Products in Santa Barbara, California. The forming and assembly was done by Kirby Morgan. The helmet had several improvements over previous designs. The viewing ports were made of one-inch plexiglass, threaded to screw into the helmet and sealed with O-rings. This eliminated the need for grills over the former glass ports and thus improved visibility. Incoming air was more effectively silenced, improving communication and preventing a loss of hearing to the diver.

KMHeH-2

The Kirby Morgan Commercial Helium Helmet. This helmet was manufactured in 1965. The design was the same as the air hat with the addition of a permanently mounted canister and venturi recirculator system. A standard Sodasorb® CO2 absorbent chemical cartridge was utilized in the canister. This helmet was the first practical commercial helium helmet with a venturi. Mr H. Dan Wilson was the first designer and user of a commercial helium helmet which used a demand system, not a venturi. His helmet preceded this hat by two years. The U.S. Navy was the pioneer of gas diving, starting in the '20s. The KMAH-1 and the KMHeH-2 were manufactured by Yokohama Diving Apparatus from 1966 to 1990.

KMAM-4

Mask

Kirby Morgan Air Mask 4. In 1965 we made a simple steady flow mask for commercial divers. Nine of these masks were made.

KMM-5

Mask

Kirby Morgan Mask 5. Later in 1965 we manufactured a fiberglass mask that was equipped with a steady flow valve and demand regulator. It had a rigid earphone on one side and used a SCUBAPRO® demand regulator.

MCSHX-3

The Morgan Clam Shell. Designed to be dry over the entire head with a neck seal, it was not successful, and was not used beyond tank testing. The primary problem was leaking in the joint between the front and rear of the hat.

KMCSHX-4

Kirby Morgan Clam Shell Helmet. The Kirby Morgan Clam Shell Helmet was designed and made in 1966 under contract with the U.S. Navy Experimental Diving Unit. The helmet was designed for use with semi-closed circuit breathing systems. The rear of the helmet was free-flooding. Only one prototype was made and tested.

KMCSHX-5

Kirby Morgan Clam Shell Helmet.The next progression in clam shells, this helmet used a demand regulator as a back up breathing system. The main breathing system was a back mounted semi-closed recirculator. This photograph shows Kirby suited up for a test, using a chest mounted breathing bag on a venturi recirculator. This helmet was free flooding in the rear and was made of fiberglass. Only one was made in 1966.

KMSLH-7

Kirby Morgan SemiLite Helmet. At the same time the clam shell series was being made, the SemiLite fibreglass helmet was designed and manufactured. A face seal separated the face area of this helmet from the back. The first was made in 1966. In all, 36 SemiLites were made and sold. The helmet was discontinued due to lack of time and funding. This helmet was the direct forerunner to the Kirby Morgan SuperLite® 17.

KMSLHX-8

Kirby Morgan SemiLite. One modified version of the SemiLite was made and tested. The balance was not right so the helmet was not manufactured.

KMM-6

Mask

Kirby Morgan Mask 6. Two earphones, located in a hood and protected by metal cups improved hearing in this mask. All masks up to this one had glued in face cushion/seals. A U.S. Divers® demand regulator was used on this mask which was made in 1966.

KMB-7

Mask

Kirby Morgan BandMask 7. The glued in face seals were troublesome, so we made the hood/face seal removable with a simple two screw band (the Kirby Morgan BandMask) The earphones were placed in pockets in the hood which made replacement easier. We started making our own regulators that were adjustable by the diver when in use. This mask was made in 1967.

KMB-8

Mask

Kirby Morgan BandMask 8. This was the first of our masks to sell on a large scale. It had several improvements over the 7, primarily the provision for attaching a bail out bottle for emergency breathing gas supply. This mask was manufactured in 1967 through 1969.

KMCSH-6

Kirby Morgan Clam Shell Helmets. This was the final version of the early Kirby Morgan Clam Shell Helmets. The hinge point was at the front. It was made of fibreglass and was free-flooding in the rear. Twelve of these helmets were made in 1968 for the U.S. Navy, & eight for Commercial use. Several dry head versions of this helmet were tested but were not successful. The wet head version had limited success.

KMB-8 1/2

Mask

Kirby Morgan BandMask. Licensed for manufacture by U.S. Divers in 1969. The side valve was changed in 1970. The replacement side valve had restricted orifices and this mask should not be used in excess of 125 ft.

MHX-9

Unnamed Helmet. This unnamed helmet was designed to be used with a rubber mask section inserted into the forward part of the helmet. One was made and tested.

MH-10

Morgan 10 Recirculator Helmet. This hat was designed in 1971 to be used with the General Electric Mark 10 closed circuit breathing system. The side mounted tubes were connected to hoses that ran breathing gas to and from the back mounted recirculator. A unique hood that was easily removable and adjustable was used on this unit.

MH-11

Morgan 11 Recirculator Helmet. This helmet was similar to the MH-10 with the addition of a demand regulator which was used as a backup breathing system. It differs very little from the BandMask design in appearance. The gas flow tubes are provided for use with the Westinghouse supplied U.S. Navy Mark 11 breathing system. The diver's head was dry in this hat.

KMB-9

Mask

Kirby Morgan BandMask 9. With an improved side valve, a change in the adjustable regulator handle and an injection molded plastic main frame. It was made by U.S. Divers from 1973 to 1975.

MHX-12

Morgan 12 Experimental. This dry helmet was designed to attach to a BandMask. A rubber hood liner inside the hard helmet provided a dry environment for the diver's head. Two versions were made. This design led to the KMH-16.

KHX-13

The Bucket Hat. This helmet was made as a joke, but several important findings were made as a result of water testing this unit. The helmet dives quite well and is surprisingly comfortable.

MHX-14

Morgan 14 Experimental Helmet. This helmet had a rubber insert in the front which isolated the diver's face from the rest of the helmet to improve the operation of the demand regulator. Water tests were not favourable, so work on this hat was stopped.

KHX-15

The Kirby 15 Experimental Hat. One was made and sold to the U.S. Navy. It was made of fibreglass and fitted with a simple steady flow breathing system. This hat was used as a platform on which to test a new neck dam and yoke system. The rubber neck dam (seal) is attached to a metal band that is clamped with a cam lever around the circular neck area of the helmet. The yoke system provides a closure at the bottom of the helmet that is smaller than a diver's head and securely fastens the hat to the head.

KHXD-15

The Kirby Experimental Demand 15. This helmet had several features that were new. A silenced servo demand regulator was positioned on the side of the hat. One was made and tested. The overall size of the helmet required counter balancing weight that made it heavier than we liked.

KMB-10

Mask

Kirby Morgan BandMask 10. U.S. Divers made this mask from 1975 until 1988 when production ended. It was also named the U.S. Navy Mk. 1 Mask. In 1988 Morgan bought the Commercial Diving Division of U.S. Divers. This included the rights and tooling to the KMB-10. At the time of the buy-out, the KMB-10 design was in need of improvement to the level of the current Kirby Morgan designs. This was done and the improved mask was named the KMB-28.

KMH-16

The Kirby Morgan Helmet 16. This helmet was an add-on hat for the KMB-10 BandMask. A rubber hood inside the fiberglass helmet provided a dry head environment for the diver. The neck seal clamped in place with a cam-action band similar to the SuperLite-17.

SuperLite® 17B

The SuperLite® 17B Commercial Diver’s Helmet was introduced in 1975. It was the culmination of all the years of testing and alterations by Kirby Morgan. This helmet set the working standard for the commercial diving industry worldwide for many years. Many thousands of underwater hours have proved the design to be dependable, comfortable, and extremely safe. The 17 continues to be the most widely used commercial diving helmet in the World.

KMB-18

Mask

This fiberglass mask incorporated many improvements over the KMB-10. Manufacturing began in 1976 by Diving Systems International. It was named the HeliOx-18 at first. Several customers believed it was only for use with mixed gas so the name was changed to DSI-18 until 1988. With the buy-out of the Commercial Diving Division of U.S. Divers the name "Kirby Morgan" was regained by Morgan and the KMB -18 continues to be manufactured today.

The SuperLite 17 Krasberg

This was a highly modified 17B designed for the Krasberg reclaim system.

The SuperLite 17 Dräger

This was a highly modified 17B designed for the Dräger reclaim system and is no longer in production. According to Bev Morgan, "Somewhere around 1980, Kirby left the company. He was in and out, working on projects until 1986, when we had a parting of the ways. We remain good friends and will probably work on mutual projects again someday."

EXO-26

Mask

Bev Morgan, collaborating with Pete Ryan, the head engineer at Diving Systems, designed the EXO-26 Mask. This mask was their first attempt at injection molding an entire product. Though the tooling was quite expensive, the cost per part was significantly lower, enabling them to compete with other molded masks in the market. Retailing for less than half the price of a BandMask, the EXO-26 has performed well and cultivated a loyal customer base that appreciates its simple design.

The US Navy Mk. 21

A slightly modified SuperLite 17B has been in production for the U.S. Navy since 1988. Designated as the Mk. 21, it is also available to the civilian market. Bev Morgan explained that the company worked diligently to enhance its production capabilities to meet the standards required for manufacturing U.S. Mil-Spec (military specifications) grade products. After implementing some modifications, the U.S. Navy awarded the company a contract for a significant number of helmets. Since 1988, the Mk. 21 has served as the standard deep-sea diving helmet for the U.S. Navy, now replaced by the KM 37 and 97.

KMB-28

Mask

Kirby Morgan BandMask 28. This mask is nearly identical to the KMB-18, with the primary difference being the main frame which is injected molded. We reworked the KMB-10 mold, changed molding procedures and are using a new, stronger material. This together with utilizing the other improvements we were using on the KMB-18 has updated this mask to the current state of the art.

SuperLite® 27

The SuperLite® 27® was the first Kirby Morgan® helmet to feature the new all metal bottom end. First introduced in 1991 the new all metal bottom end consisted of a helmet ring with an O-ring main seal, a locking collar with an adjustable neck pad, a set of neck rings that allowed the diver to use a neck dam, or mount their dry suit directly into the neck ring system. This new helmet ring/neck dam ring system also featured an externally adjustable chin strap.

SuperLite 17B with Jewel Return Line Regulator

This model is a slightly modified 17B model designed for the Divex reclaim system. Retaining the shape and appearance of the 17B while utilizing the SuperLite-27 neck ring and yoke system, this helmet is the forerunner of the 17K. It is currently manufactured and sold through Divex, U.K.

SuperLite® 17C

The SuperLite® 17C was designed for the British Royal Navy and is one of the first two Kirby Morgan helmets that had the new “all metal bottom end.” One of the important features of this helmet is that it was designed to be fitted with a gas reclaim system. A few other unique attributes of the 17C are that its ability to accept the reclaim unit precluded the newer, "modular" communications; so instead, it has communications like earlier 17A/B helmets. Also, it has its own weighting system and on top: three large flat brackets instead of just one handle in the centre, as on all other helmet models. The 17C paved the way to the more standardized 17K, which in turn gave rise to the KM 37.

M-48 SuperMask®

The M-48 SuperMask is a lightweight, modular full-face mask that enables quick and easy adaptation to various self-contained underwater breathing apparatuses and surface-supplied systems.

The mask frame and rigid components are constructed from high-impact plastic. The face seal is crafted from the highest quality silicone, which conforms to the diver's face. The modular, removable mouth pod is designed for quick interchangeability, allowing the diver multiple breathing gas options. Additionally, the mask is designed to accommodate various wireless communication configurations.

The removable lower pod is a feature unique to the SuperMask. When diving, the pod can be easily removed and replaced on the mask, allowing the diver to buddy-breathe, use a snorkel or an octopus, or perform an "in water" gas switch.

With the pod sealed to the mask, the flexible silicone pod cover allows divers to quickly place the regulator mouthpiece in their mouths or to dive without it for communication. When the mouthpiece is in, the regulator can be used even if the pod is not sealed to the mask. The mask can also be used with surface supplies. Several different pod configurations have been developed for both open-circuit and rebreather use.

Kirby Morgan® 37

The model 37 Kirby Morgan® Helmet made it clear that this new hat was an improved model and not just another 17. A new and very advanced exhaust system, the Quad-Valve Exhaust, was added to the 17K to make it the 37. The new exhaust system made the 37 very dry and yet lowered the breathing resistance.

Kirby Morgan® 57

The KM 57 shares the same components as the KM 37 except for the breathing regulator. The KM 57 comes equipped with the SuperFlow® 450 which is a balanced regulator. The SuperFlow® 450 balanced regulator will automatically compensate for a wider range of inlet pressures than a non-balanced regulator, is made from a robust stainless steel investment casting, has an elevated performance at the upper end of the breathing cycle, and has a much smaller profile than the REX regulator.

Kirby Morgan® 47

After extensive testing of the EXO®-BR by the US Navy and Dive Lab it has been determined that the balanced version of EXO® Regulator is one of the highest performance regulators in the world. Kirby Morgan® then took this knowledge and redesigned the fibreglass shell of the KM 37 to accept an EXO®-BR regulator for evaluation. Eventually, the development of a stainless steel version of this high-performance balanced regulator was designated, “REX®.” The new “REX®” Regulator was adapted to the new helmet shell, and the KM 47 was born.

Kirby Morgan® 77

The KM 77 is the first all metal helmet (all main components are 316L stainless steel) that Kirby Morgan® has produced. It comes standard with the high performance REX® Regulator though it features a Pod System that allows the mounting of the SuperFlow® 350, SuperFlow® 450 as well as reclaim or rebreather systems. It also has a newer design side block that has an integrated emergency valve system.

Kirby Morgan® 37SS

This is basically the KM 77 helmet with the SuperFlow® 350 regulator featured on the KM 37. It also has the Pod System that allows the mounting of other regulators. Advancements in computer aided design engineering and metal manufacturing techniques have allowed Kirby Morgan® to offer these high quality all metal helmets.

Kirby Morgan® 97

The Kirby Morgan® 97 features the 455 Balanced Regulator. The 455 is an all stainless steel regulator with superior breathing performance and the added advantage of upcoming compatibility with the SL 27, 17C, KM 37, KM 37SS, KM 57 helmets as well as the KMB 18 & 28 Band Masks. The overall performance of this regulator is outstanding and sets a new performance standard for commercial diving helmets and band masks.

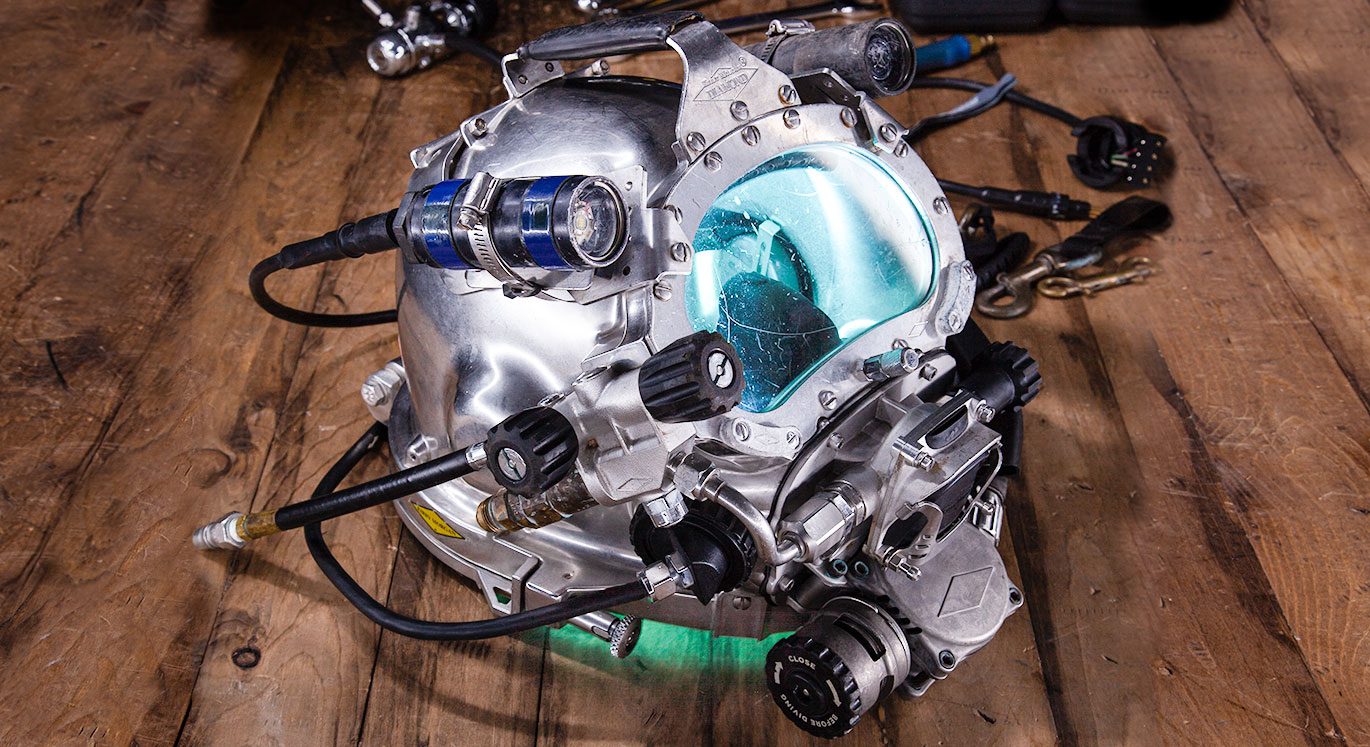

Kirby Morgan® Diamond

The Kirby Morgan® Diamond is the next modular variation to the KMDSI stainless steel helmet. When the KM Diamond is attached to our stainless steel helmet shell the diver can operate in either a surface exhaust or ambient water exhaust diving mode.

Surface Supplied MOD-1

The Surface Supplied MOD-1 is the latest addition to our modular Full Face Mask product line. The newly added Surface Supplied Pod is secured to the MOD-1, constructed of specialty polymers/elastomers and machined components of titanium and high-grade stainless steel.